Struggling to choose between COB and regular LEDs for your project? The wrong spotlight can ruin the whole atmosphere.

A COB spotlight uses a high-density chip-on-board design that offers smoother, more focused lighting compared to regular LED arrays. It also simplifies circuitry and improves visual consistency.

COB lights aren’t just “brighter.” They change the way light feels and looks. Let me walk you through the real differences that matter in commercial lighting, based on what I’ve seen in two decades of hands-on project experience.

What does COB stand for in LED lighting?

Many people think COB just means “brighter LEDs.” That’s only part of the story.

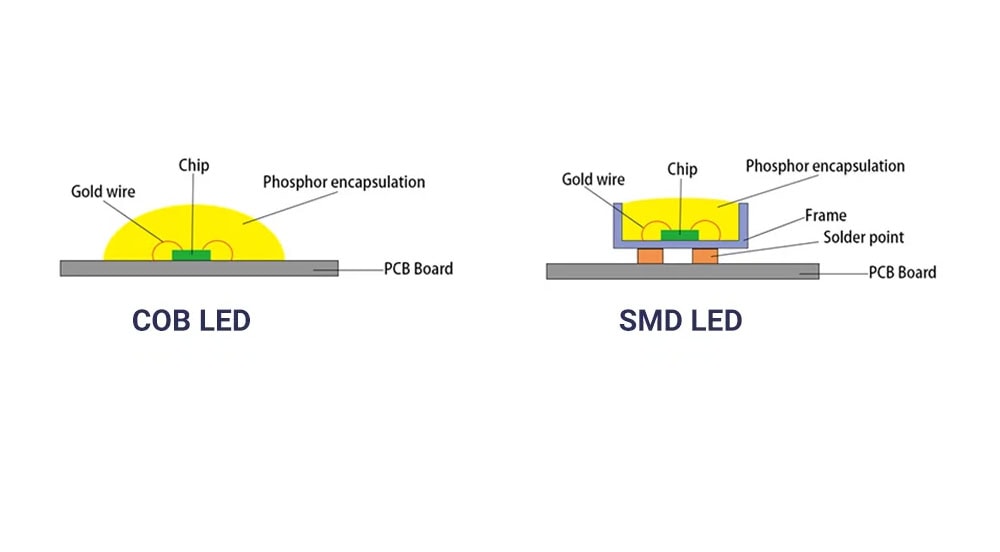

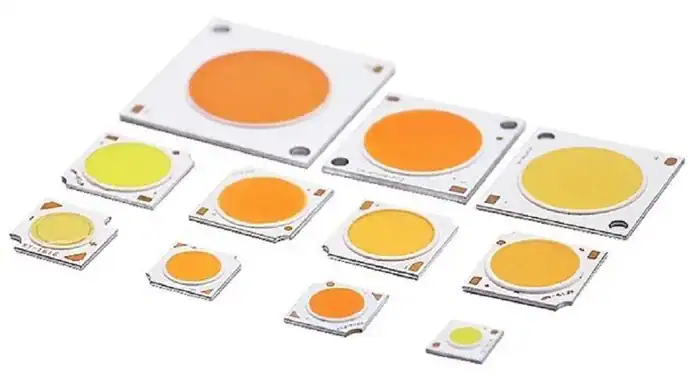

COB stands for “Chip on Board1,” a technology where multiple bare LED chips are mounted directly on a single substrate and then covered with a uniform phosphor layer.

When I first used COB for a retail lighting job over ten years ago, what struck me wasn’t the brightness—it was the softness. Unlike traditional SMD LEDs that look like a dotted grid, COB gives you a continuous beam of light with no harsh spots. This is because the chips sit so close together, they blend into one seamless light source.

This uniform glow brings two benefits: the light looks cleaner, and it casts fewer shadows. That matters a lot when lighting product displays, retail shelves, or art pieces. I always remind clients: light isn’t just about lux levels—it’s about how it makes people feel.

Technically, COB also simplifies the drive circuit. You only need one pair of electrodes, which means fewer points of failure. That’s another reason why high-end commercial lighting often chooses COB, especially in spaces where consistent visual experience matters more than raw brightness numbers.

How do COB spotlights compare to SMD and panel lights?

Choosing COB over SMD or panels isn’t always the best move. It depends on what you’re trying to achieve.

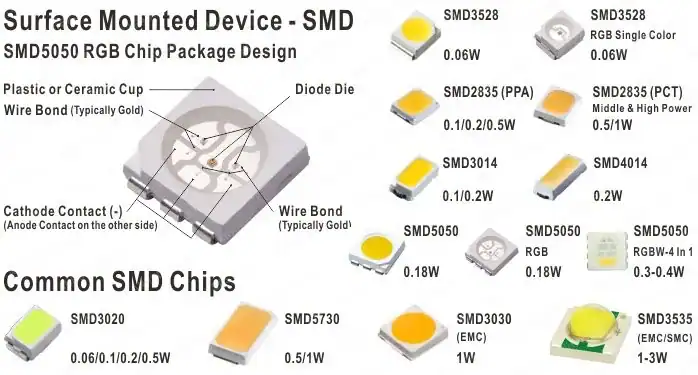

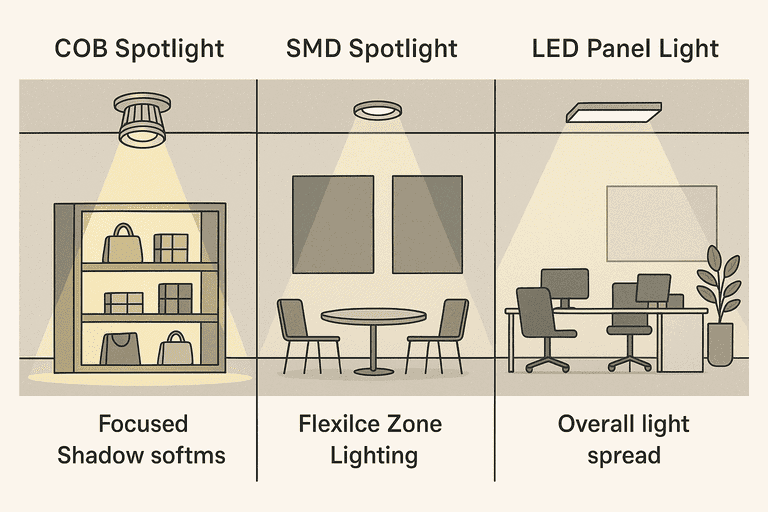

COB is better for focused, clean lighting, while SMD and panels2 give you flexibility and lower costs.

Here’s the comparison I often share with clients during design meetings:

| Feature | COB Spotlight3 | SMD / Panel LED |

|---|---|---|

| Beam Control | Stronger focus with reflectors | Flexible beam shaping with layout |

| Light Uniformity | Soft, shadow-free | Can have hotspots or rings |

| Initial Cost | Higher due to dense packaging | Lower, uses common modules |

| Circuit Simplicity | One pair of electrodes | Complex wiring for arrays |

| Maintenance | Whole module may need replacing | Easy to swap damaged units |

| Best Use Case | Display, gallery, product highlight | General lighting, ambient, backlight |

In some renovation projects, I run lighting simulations using Revit4 and Dialux5. Sometimes, we discover that SMD with a diffuser gets the job done just as well—at a lower cost and with more control over lighting zones. But for display areas or retail showcases where the quality of light makes a visual impact, COB still wins.

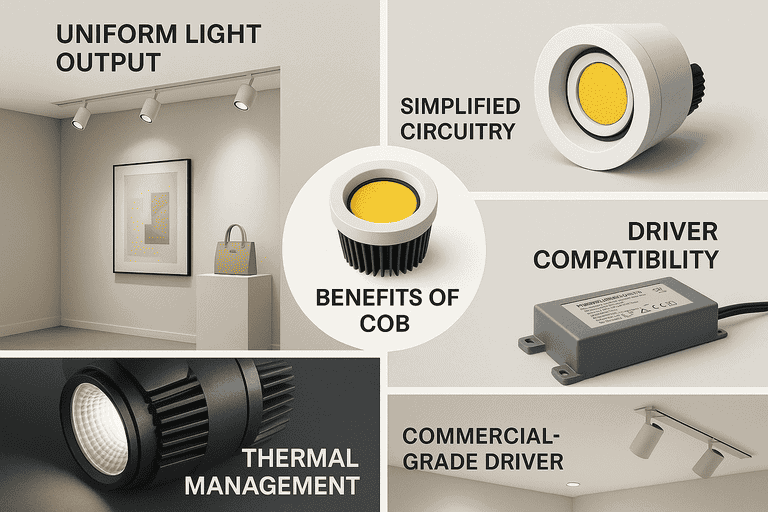

What are the main benefits of COB spotlight technology?

COB is not just about how it looks—it’s about performance, reliability, and design clarity.

COB spotlights deliver uniform light quality, simplified circuits, and better control, all of which are key for high-demand commercial spaces.

Here’s where I’ve seen COB shine in real projects:

-

Light quality6 – One solid light source means fewer shadows and smoother gradients. That’s critical in retail and gallery spaces where you want the light to “wash” across a surface.

-

Circuit design – Fewer components means fewer things that can break. When you’re running a system 14 hours a day, that stability matters.

-

Thermal management7 – This is the hidden battle. COB chips get hot fast. If the heat isn’t managed well—using thick heatsinks, aluminum frames, or even active cooling—the light may fade or fail early. I’ve had to troubleshoot failed installations where clients used cheaper COB models with poor heat paths. Now, I always make thermal design part of the product datasheet and planning docs.

-

Driver matching – Because COB draws a lot of power quickly, the driver needs to handle ripple, startup surge, and dimming protocols. I’ve had projects where TRIAC dimmers flickered like a disco—just because the driver wasn’t matched to the COB’s current profile.

All these benefits come together when the system is designed properly. That’s why I don’t just sell lights. I work with clients to match COB specs to their real installation needs.

Are COB spotlight8s better for commercial or residential use?

COB is ideal for commercial use where lighting quality and reliability must stay consistent under heavy daily use.

COB works best in commercial spaces9 like showrooms, stores, and galleries. Residential lighting usually doesn’t need COB unless you want museum-quality spotlights.

Most of my COB spotlight8 clients are commercial. They include German architecture firms designing retail chains, or hotel designers looking for strong, glare-free accents. Why?

-

Longevity under stress – COB chips are often built into aluminum bodies with excellent cooling. This helps them stay bright even after thousands of hours.

-

Visual clarity – In commercial spaces9, how your product or artwork looks can affect sales or perception. COB gives a premium, shadowless glow that you can’t get with basic panels.

-

Driver reliability – In commercial spaces9, drivers must run all day. Many home fixtures don’t have drivers that are rated for commercial runtimes. I’ve replaced “home COBs” that burned out fast in retail environments.

That said, I’ve had homeowners ask for COB in kitchens or home theaters. If the budget allows and they want that focused look, it can work—but you need to choose drivers and fixtures built for constant use.

Conclusion

COB spotlights offer smoother light, better focus, and long-term reliability—making them the smarter choice for high-end commercial lighting where every detail matters.

-

Explore this link to understand how Chip on Board technology enhances LED performance and lighting quality. ↩

-

This resource will provide insights into the cost-effectiveness and versatility of SMD and panel lights compared to COB. ↩

-

Explore this link to understand why COB Spotlights are preferred for focused and clean lighting in specific applications. ↩

-

Explore this link to enhance your Revit skills specifically for lighting design, improving your project outcomes. ↩

-

Explore this link to understand Dialux’s features and benefits for effective lighting simulations in design projects. ↩

-

Understanding light quality in COB technology can enhance your lighting design, ensuring optimal performance in commercial spaces. ↩

-

Exploring thermal management in COB technology is crucial for longevity and efficiency, preventing failures in high-demand environments. ↩

-

Explore the advantages of COB spotlights in commercial settings, including longevity and visual clarity, to enhance your lighting choices. ↩ ↩

-

Learn how tailored lighting solutions can improve aesthetics and functionality in commercial spaces, boosting sales and customer experience. ↩ ↩ ↩