Most people pick IP65-rated lights and assume they’re all the same. They’re not. A poor IP65 downlight can cause failure, water damage, or costly rework. Here’s how to avoid that.

To choose the best IP65 LED downlight for commercial spaces, check five key areas: ingress protection integrity, thermal performance, optical design, control compatibility, and maintenance logistics.

The sticker says IP65—but what’s really behind that label?

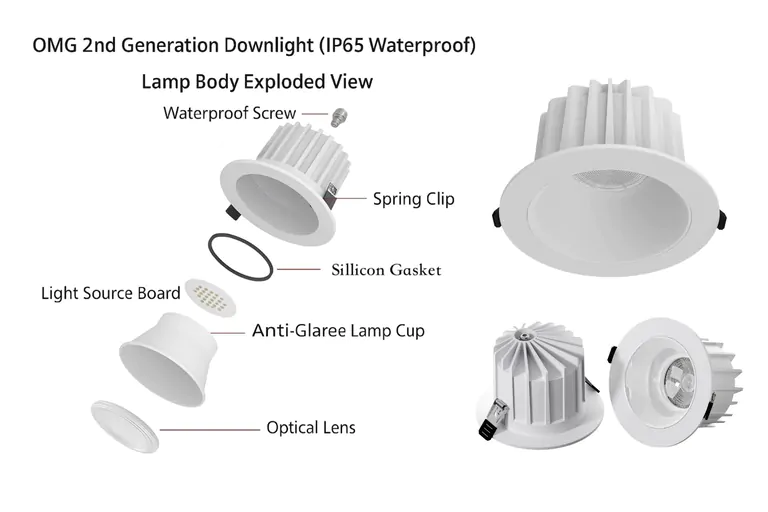

Some assume IP65 means full protection. But it only tells part of the story. You still need to verify how the manufacturer implemented sealing, gasket quality, and driver protection.

Check that the sealing between the lens, trim, body, and rear enclosure is robust. Weak gaskets degrade over time—especially in areas with UV, vibration, or heat-cool cycles like kitchens and canopies. Even if the optics are sealed, if the driver compartment isn’t, moisture creeps in. That’s how many "IP65" failures begin. Also, look for drainage channels or pressure-balancing vents, especially in humid climates.

What technical specifications should procurement managers review?

It’s easy to compare wattage and lumens, but these numbers miss hidden performance killers. A spec sheet doesn’t always reflect real-life behavior in harsh or tight-ceiling environments.

A reliable downlight should show thermal simulation data. How does the light’s output or lifetime change at 45°C or 60°C ambient? Most don’t show it. That’s a red flag. Favor heat sinks with visible fins or thick aluminum bodies. Check the driver’s rated operating temperature range. I’ve seen beautiful spec lights burn out in under a year because their driver was wedged into a hot plenum with no airflow.

| Specification | What to Look For | Why It Matters |

|---|---|---|

| IP Rating Implementation1 | Gasket quality, sealed drivers, drain design | Prevents early failure from moisture ingress |

| Thermal Management2 | Heat sink design, derating curves, driver temp rating | Ensures long life in real ceilings |

| Optical Control3 | UGR value, beam options, lens design | Avoids glare complaints and improves comfort |

| Control Compatibility | DALI, 0–10V, wireless protocols | Seamless system integration |

| Maintenance Features | Tool-less access, corrosion resistance, modular parts | Cuts service cost and avoids future issues |

Should you prioritize wattage, beam angle, or lumen efficiency4?

Most procurement specs still list wattage and efficiency first. But in real use, optical comfort and flexibility are what make downlights work or fail in a space.

Don’t get stuck comparing lm/W alone. A fixture might be 110 lm/W, but if it blinds staff or throws light where you don’t need it, you’ll get complaints. Instead, aim for a balance. Choose fixtures with deep-set optics or lenses that control glare. Request beam angle options5—narrow for accents, wide for general wash. Always check for UGR ≤ 19 if it’s for office or retail.

How do IP65 downlights perform in offices compared to retail spaces?

You’d think a downlight is a downlight. But offices and retail zones have very different needs—and mistakes here create bad experiences.

In offices, consistent low-glare6 light is key. Even a slightly harsh fixture can cause fatigue over time. Go for wide beams, soft lenses, and deep optics. In retail, accents matter more. You want flexibility—narrow beams to highlight products, tiltable heads for displays, and better color rendering (CRI 90+). But both zones benefit from IP65 in bathrooms, kitchens, or semi-outdoor entries. So, match the optic to the space, not just the IP rating.

| Application | Lighting Priority | Downlight Features to Match |

|---|---|---|

| Office Ceilings | Low-glare, wide distribution | UGR ≤ 19, diffused lens, deep-recessed LED |

| Retail Zones | Accent control, vivid product light | Narrow beam options, tiltable gimbals, CRI90+ |

| Washrooms/Entrances | Humidity & moisture resistance | IP65 sealing, anti-corrosion finish |

What mistakes should you avoid when selecting IP65 lighting?

Even experienced pros fall for this: choosing based on headline specs without considering real-life usability. I’ve made that mistake before.

One common error is ignoring how the fixture mounts. If it needs tools or tight tolerances, and you’re installing hundreds, the labor adds up. Another is skipping batch consistency7. For big rollouts, ensure you get color consistency8 (ΔE < 1) between batches. Also, avoid “sealed forever” designs. If you can’t access the driver or LED module, replacement gets messy. Always ask: Can this be cleaned easily? Will this survive detergent or steam in food zones?

Conclusion

A good IP65 downlight isn’t just water-resistant. It must be thermally solid, optically comfortable, control-ready, and easy to maintain.

-

Exploring IP ratings helps you choose lighting that withstands environmental challenges, ensuring durability and performance. ↩

-

Understanding thermal management is crucial for ensuring the longevity and efficiency of lighting systems. ↩

-

Explore this resource to understand how Optical Control enhances comfort and reduces glare in lighting systems. ↩

-

Understanding lumen efficiency helps you choose lighting that maximizes brightness while minimizing energy use, ensuring cost-effective solutions. ↩

-

Exploring beam angle options can enhance your lighting design, allowing for better control of light distribution and improved visual comfort. ↩

-

Learn about the significance of low-glare lighting in offices to improve comfort and productivity. ↩

-

Understanding batch consistency is crucial for ensuring uniformity in large installations, which can save time and costs. ↩

-

Understanding color consistency is crucial for ensuring uniformity in lighting, especially for large installations. ↩