Installing LED downlights the wrong way can lead to overheating, flickering, and costly rework. That’s why planning matters more than tools.

The best way to install LED downlights in a commercial space is to combine site assessment, thermal clearance, layout simulation, and strict step-by-step installation, ensuring both performance and long-term safety.

I’ve worked on retail chains, hospitality projects, banks, and malls. In every case, it wasn’t the LED itself that caused issues—it was poor coordination or shortcut installation that ruined the outcome.

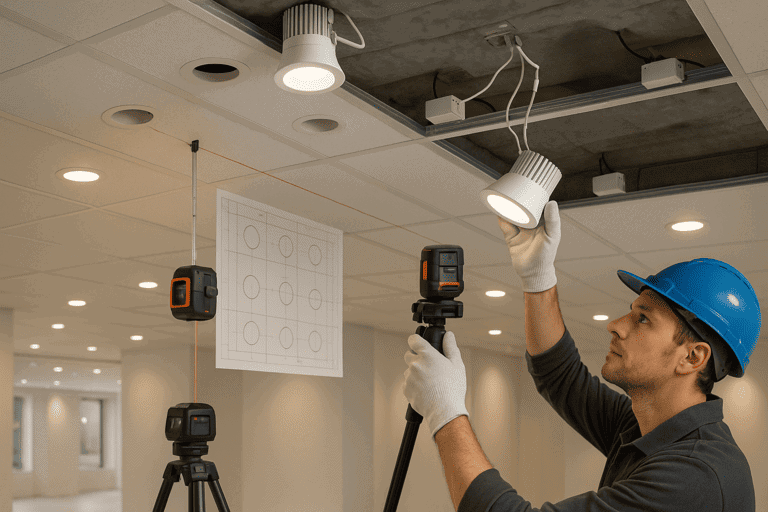

How do you plan the layout of recessed LED downlights?

Layout starts before the first cut. You need to simulate light behavior, check physical structures, and align lighting goals with ceiling limitations.

To plan a layout, simulate light distribution, mark zones for ambient and display lighting, avoid clashes with HVAC1 and fire systems, and leave margin for heat flow and cable runs.

Here’s what I do before installation starts:

- Run a lighting simulation2 using tools like DIALux3 or AGi32. It gives a preview of lux levels, shadows, and brightness uniformity.

- Define light layers—ambient, task, and accent. Downlights usually serve ambient and partial task lighting.

- Overlay with HVAC1 and MEP drawings to make sure lights don’t hit ducts or fire sprinklers.

- Match fixture specs to ceiling conditions—some ceilings won’t fit deep fixtures or allow driver boxes4 above.

- Mark every light’s position with ±2 mm tolerance. Get approval from the design team and site foreman.

I always advise clients: don’t just “grid” the ceiling. Start with what needs lighting—then build the grid around it.

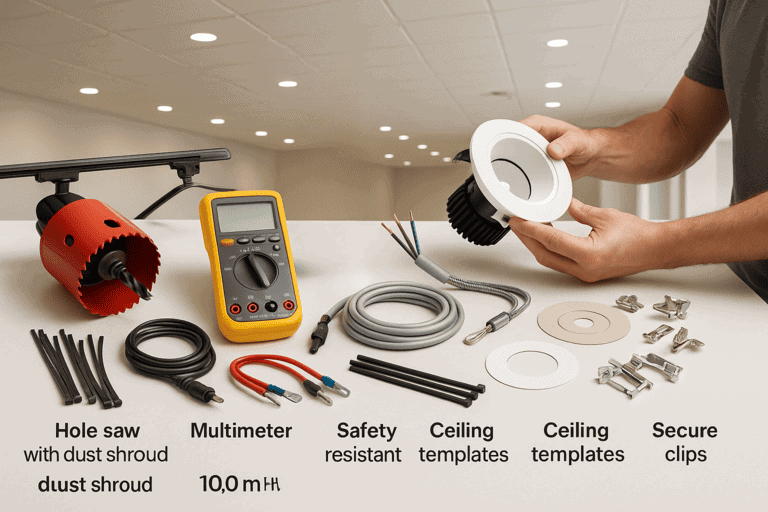

What tools and accessories are needed for proper installation?

You’ll need more than a drill. Commercial installs demand precision, safety, and structural compatibility.

Essential tools include hole saws5, wire testers, fire-rated sealant6, cable ties, brackets, and sometimes suspension kits or insulation barriers.

Here’s my go-to list for downlight installs:

| Tool / Material | Function |

|---|---|

| Hole saw with dust shroud | Clean ceiling cutouts |

| Multimeter / continuity tester | Ensure safe circuits |

| Heat-resistant wiring | Maintain safe operation over time |

| Secure clips / hangers | Lock fixture to structure |

| Safety tether wire | Prevent lamp drop during install |

| Fire-rated sealant | Close ceiling gaps for code compliance |

| Flexible conduit or cable tray | Organize wiring layout |

One mistake I often see: skipping the safety tether. On high ceilings, that’s a disaster risk. Also, never let contractors cut holes without templates. It ruins fixture alignment.

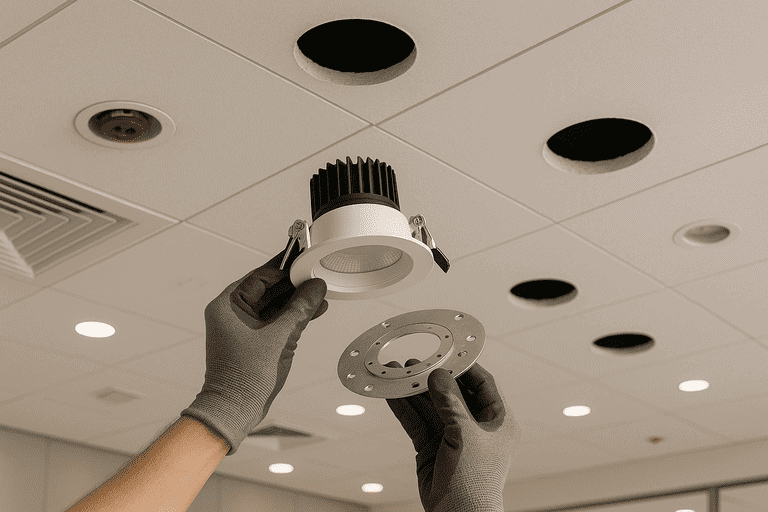

Can LED downlights7 be installed without damaging false ceilings8?

Yes—if done right. The trick is precision cutting, coordinated MEP layout, and using fixtures designed for that ceiling type.

LED downlights7 can be installed cleanly in false ceilings8 using templates, proper mounting kits, and careful coordination with HVAC and fire safety layouts.

False ceilings—whether gypsum board, aluminum panels, or T-grid—need special care:

- Use cutout templates provided by the manufacturer.

- Avoid structural members or ducts behind the ceiling.

- Use backing plates or support kits if the panel can’t hold the fixture weight.

- Seal holes with fire-rated compounds in rated ceilings.

One of my hotel projects had dozens of downlights in gypsum. The contractor used rough manual cuts—every fixture sat uneven. We had to remove and refinish the ceiling border. Now I insist on mock-up installs before approving large rollouts.

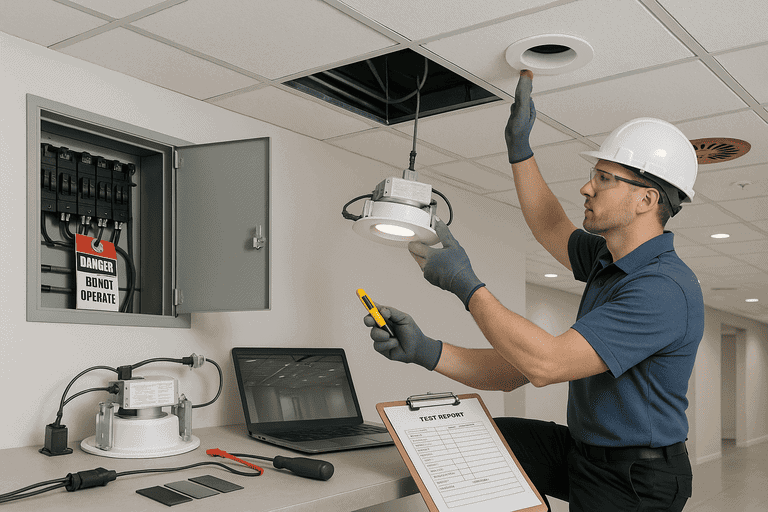

What are the safety precautions for commercial lighting installation?

Safety starts at planning—and follows through every step to final testing.

Key precautions include shutting down circuits, using protective gear, avoiding overloading lines, and following fire seal protocols during installation.

Here’s what I include in every install briefing:

- Shut off the power at the panel and place lockout tags.

- Wear safety gear9—gloves, eye protection, anti-slip shoes.

- Use test pens to verify power-off before wiring.

- Mount all drivers and fixtures per spec—never hang by cables.

- Test every fixture individually before ceiling access closes.

- Check voltage drop on long cable runs—especially for multi-zone installs.

- Seal all gaps with fire-approved sealants10 in rated ceilings or near HVAC zones.

And always document: take install photos, wire maps, and issue a test report. One client of mine didn’t keep a log—months later, when a light failed, no one knew which circuit it belonged to.

Conclusion

The best LED downlight install in a commercial space combines good planning, smart layout, correct tools, and strict safety discipline. Get those right, and the lights will shine long after the project is done.

-

Understanding HVAC’s role is crucial for effective lighting design, ensuring safety and efficiency in installations. ↩ ↩

-

Explore this link to discover advanced tools that can enhance your lighting design process and ensure optimal light distribution. ↩

-

Explore this link to understand how DIALux enhances lighting design with simulations, ensuring optimal light distribution. ↩

-

Understanding driver boxes is crucial for ensuring proper installation and functionality of recessed LED downlights. ↩

-

Learning about hole saws can enhance your installation skills, ensuring clean and precise cuts. ↩

-

Understanding fire-rated sealant is crucial for ensuring safety and code compliance in installations. ↩

-

Explore this link to learn essential tips and techniques for a flawless LED downlight installation. ↩ ↩

-

This resource provides valuable insights on maintaining the integrity of false ceilings during installations. ↩ ↩

-

Exploring this link will help you understand essential safety gear to protect yourself during installations. ↩

-

This resource will provide insights into effective fire-approved sealants crucial for safety in lighting installations. ↩